Three Big Factors To Consider.

......Fire rating & testingCellulouse insulation has been

manufactured to meet the amended CPSC standard for flame resistance and corrosiveness of cellulose insulation. Cellulouse is a class one fire-rated building material. It meets the stringent fire safety standards of the U.S. Consumer Product Safety Commission. Tests have proven that cellulose insulation actually increases the fire resistance of a wall from 22% to 55%, while fiberglass insulation was found to be no better than a non-insulated wall. Research shows that the fire retardant capabilities of Cellulouse and its density, keeps air from feeding a fire. |

So a structure insulated with cellulouse will burn slower, which could very well provide the time it takes to save a life. Fiberglass, on the other hand, melts which can allow fires to spread quickly. |

See

Fire Wall Design

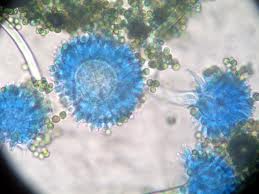

.....Mold & Fungi Resistance

|

To date the serious reported cases of mold growth in insulation have all involved fiberglass, but no insulation or building materials are in themselves the cause for mold growth.

The key to stopping mold growth in our buildings is halting moisture; mold and fungus problems aren't inherent in a building that is relatively dry. Mold is everywhere in the environment. Given heat, moisture and organic material it will grow. Fiberglass and other inorganic materials quickly become coated with organic materials. Fiberglass contains no fungicidal additives, so it soon becomes a very hospitable environment for fungal growth because of air infiltration which may lead to moisture migration. When using dense packing cellulose insulation it will create a continuous even layer of insulation. Pipes, wires, ductwork and electrical outlets are no problem for cellulose insulation because it is blown into the the tiniest of spaces, limiting air infiltration. |

Cellulose Insulation contains Board Defence (EPA registered No. 44757) a 100% borante at no less than 23% by weight. The inclusion of borate has

been tested for the resistance to the growth of fungi in accordance with ASTM C 739 and helps to prevent the growth of the following fungi.

|

Safety & Toxicity

|

Cellulouse meets the safety

standards of the U.S. Consumer Products Safety Commission, (CPSC) American Society of Testing Materials (ASTM), the Cellulose Insulation Manufacturers Association (CIMA), and Federal Specification HHI-515. It also complies with all requirements of the Environmental Protection Agency's (EPA) Federal Insecticide and Fungicide. No other insulation meets such exacting quality control standards. |

Cellulouse Insulation is sprayed or blown into walls, conforming to your home and surrounding you and your family with a tight and safe thermal barrier.

Standard Specifications

LICENSE #C32145

P.O. Box 4546

Kailua Kona, HI 96745

(808) 325-5888

mark@ecopacificinsulators.com

ecopacificinsulators.com

CONTACT US TODAY FOR A FREE QUOTE OR TO RECEIVE MORE INFORMATION

P.O. Box 4546

Kailua Kona, HI 96745

(808) 325-5888

mark@ecopacificinsulators.com

ecopacificinsulators.com

CONTACT US TODAY FOR A FREE QUOTE OR TO RECEIVE MORE INFORMATION